Shrinky Dink toys from the 1970s have made their way back into the spotlight—this time as a substrate for researchers in biomolecular and chemical engineering.

Researchers have figured out how to print in three dimensions, using prestressed polymers rendered from Shrinky Dinks to transform flat cutouts into 3-D objects with the application of light.

Researchers Michael Dickey and Jan Genzer , biomolecular engineering professors, do this by printing a series of lines onto a piece of the special paper. When it is then exposed to light, it will fold along the lines to create three-dimensional objects. Using this process they can print cubes, pyramids, or any variety of complex geometric shapes.

The key is that they start out with a prestressed polymer sheet. This, in its most basic definition, is a flat object made of repeatedly linked molecular units arranged like a chain. In layman’s terms, it’s a piece of plastic that will shrink when heated—a Shrinky Dink . According to Dickey, common examples of prestressed polymer sheets are wax paper, cellophane or overhead transparencies.

“So [we picked] Shrinky Dinks because they are commercially available, so we can just buy a bunch and don’t have to make the materials,” Dickey said. “There’s no reason that you would have to use this per se—it’s just that we can buy them and run them through a printer.”

The researchers then take advantage of how these polymers react so dramatically to heat in order to make them fold. Darker colors, like black, will absorb a lot more light and become hotter faster than lighter colors, like the original translucent white of the polymer sheets. By printing black lines of ink on the Shrinky Dink sheets and then shining light onto them, they cause the black lines to shrink without affecting the rest of the sheet.

“So basically we are confining the shrinking process to just a hinge, and the way we define the hinge is by patterning ink,” Dickey said. “The key is you want differential heating; you want the hinge to get a lot hotter faster than the sheet.”

This shrinking of the hinge is not uniform, however—the light heats the top of the sheet faster than the bottom. This means instead of shrinking along a plane, it creates a crisp fold.

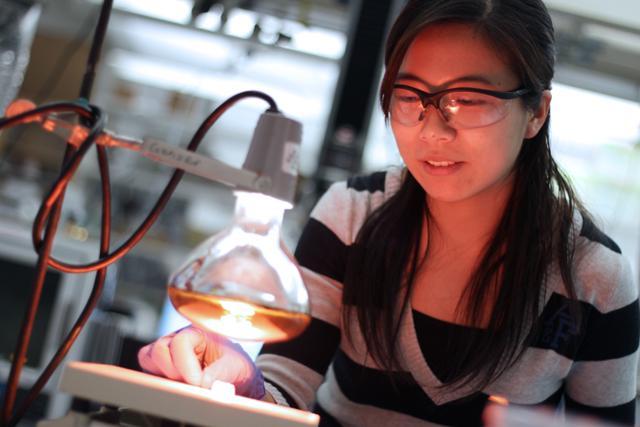

“The top surface will shrink, but the bottom surface of the polymer sheet will not, so based on this gradient it will fold,” Ying Liu, a chemical and biomolecular graduate student and the graduate research assistant, said.

They can then determine the angles of the folds using mathematical models, which are dependent on things like light, heat and the geometry of the ink mark.

“We try to use some mathematical modeling software to study how the folding depends on the temperature profile of the polymer sheet and how the folding angle can be defined by the geometry of the hinge defined by the black ink from the printer,” Liu said.

From this they’ve studied the science of the reaction. They’ve created a thermal model, are tracking the movement of energy and have published a paper about it.

“For this first paper we were trying to understand the science of it, to understand why it works. So far we haven’t demonstrated any applications, but we have some in mind,” Dickey said.

The researchers have many ideas to which this process can be applied. Anything that is now printed in a planar matter and then assembled can be automatically converted into 3-D.

“If you wanted to pattern metal wires or something like that, you could do that and it would be 2-D and then the very last step you either heat it or shine light on it, or put it in a microwave or whatever, and then it would fold up into 3-D,” Dickey said. “So that was the original motivation—we just didn’t know how to do it. And it turned out that this incredibly simple way really worked the best.”

It’s an easy and cheap process, which makes it applicable in the real world.

“I’m proud of the fact that it’s so simple,” Dickey said.

It’s actually so straightforward that you could do it at home, Dickey said. Just acquire some Shrinky Dinks , the preferred pre-stressed polymers of the researchers, run them through a printer to create the hinges (no special ink required), cut them out and stick them under your desk lamp to watch them fold themselves.

You could even use a permanent marker if you don’t have a printer, though it won’t be as precise, Dickey said. The researchers discovered the polymers’ folding property accidently by marking the sheets with a permanent marker when studying them in a more complicated way that involved trying to make them fold with microwave radiation.

Before Technician informed Betty Morris, the owner and founder of the Shrinky Dinks company, on the research using Shrinky Dinks at the University, she was unaware of the NCSU project.

Morris said she is proud of how far her products have come since they hit the toy store market in 1973.

Shrinky Dinks are now also being used in the creation of microchips, according to Morris.

“I feel pretty excited to see something like that, that’s a very new idea,” Morris said. She said she intends to investigate the NCSU project’s Youtube page and plans to try it out at home.