3-D printing is well known as a method for producing plastic objects. However, an NC State research team, Dickey’s Group, has expanded 3-D printing to metallic objects.

Dickey’s Group, led by associate professor Michael Dickey, is the first to pioneer 3-D printing using liquid metal. The breakthrough was achieved by researching new methods to manipulate the liquid metal.

Although liquid metal may sound unfamiliar, the material is found everywhere. Liquid metal is a phase of metal where the melting point is at or near the room temperature. Mercury is the best example of such material, as it is widely known and has many useful applications, from barometer to thermometer, according to Collin Eaker, a graduate student studying chemical engineering and a graduate researcher in Dickey’s Group.

“Liquid metal in general is not a name of specific material,” Eaker said. “It’s a phase of a metal. The difference is that the metals we work with are liquid at or near room temperature.”

Dickey’s Group isn’t the first to scientifically research the liquid metal, according to Dickey. Eaker said research on liquid metal has been going on for decades, with the oldest being from the ‘60s.

“We did not discover this metal, but we have pioneered new ways to study and use it by taking advantage of the fascinating properties,” Dickey said.

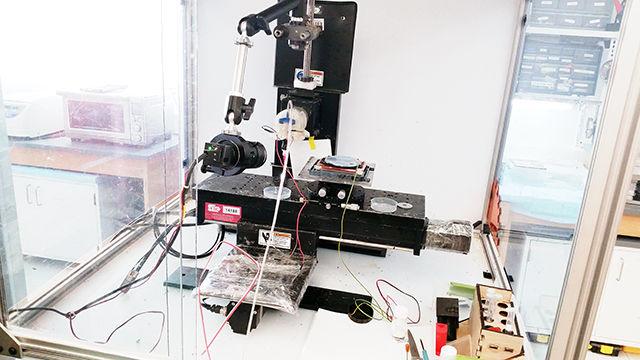

However, Dickey’s Group was the first to pioneer a new method of manipulating eutectic gallium indium, or EGaIn for short, to be used for 3-D printing.

“[EGaIn] is a mixture of two alloys, gallium and indium,” Eaker said. According to him, eutectic compositions have the lowest melting point of all possible alloy ratios.

The Dickey Group manipulated EGaIn by utilizing the surface oxide skin that forms when in contact with oxygen. The surface oxide skin is similar to rust. Unlike the rust, the EGaIn’s surface oxide skin forms a shell around the liquid metal, allowing it to be patterned for different applications.

“Our major contribution has been to utilize the surface oxide skin that forms on the metal as a new way to shape and manipulate the metal,” Eaker said. “The surface oxide skin is the solid layer that forms when the metal reacts with air.”

One application for 3-D printing metal is stretchable electronics. Eaker said stretchable electronics are electronics that can be stretched and strained beyond their normal limits. One possibility for a stretchable electronic is a biosensor for monitoring a user’s health, according to Eaker.

“These electronics have many possibilities,” Eaker said. “Imagine having biosensor that can conform to your body and measure things like glucose levels if you’re diabetic.”

During the eight years of research, Dickey said his group faced many obstacles, as there was no research done in the subject before the group started working.

“Dickey’s Group started researching around 2008-09,” Eaker said. “Finding a new technique to measure some of the basic properties and manipulating the material was challenging because people never worked in this manner before. Cleaning was quite difficult as I had to scoop up individual droplets.”

Despite the obstacles, Eaker said Dickey’s Group was overjoyed upon making the breakthrough. In addition, Eaker said the team’s research was made possible by an undergraduate researcher, Collin Ladd, who played a large role in its work.

Ladd said he was surprised about the discovery. “I had kind of been quietly working away at what had been ‘just an undergrad project’ until then,” Ladd said.

Ladd is an NC State chemistry graduate who filled the gaps in setup fabrication and prototype drafting for what turned out to be a very multidisciplinary project. Ladd currently has returned to NC State to work with Dickey.

As for 2016, Dickey’s Group hopes for another breakthrough by being the first to utilize its work to produce practical items, such as electronics, through 3-D printing.

“We hope to show that it can be utilized for 3-D printing of practical objects that include electronics,” Dickey said. “That would be an important breakthrough.”