A resurgence in the manufacturing sector could be just what North Carolina needs to stimulate the post-recession economy, and young alumni are heeding the call to not just create more high-tech products, but also to create more jobs for the state.

Manufacturing jobs saw a net gain for the first time in in 2011, after a period of workforce transitions had hurt the once powerful sector, according to a report by the North Carolina Rural Economic Center. The outsourcing of jobs was the main reason for the downturn.

In the past, manufacturing in North Carolina focused on furniture, apparel, textiles and tobacco products, but the emergence of areas like alternative energy, biomanufacturing, and the aerospace industry are changing the industrial landscape because they require more advanced skill sets and innovation.

Currently, manufacturing holds the top spot in contributions to the state’s gross domestic product, and is the state’s largest economic sector. It also provides higher than average wages to workers, a slew of products for foreign exports and the opportunity for more high-tech industries as the sector evolves.

The N.C. Department of Commerce recently added a new assistant secretary of manufacturing position to promote future “policy development” in the manufacturing arena, according to the state’s chamber of commerce.

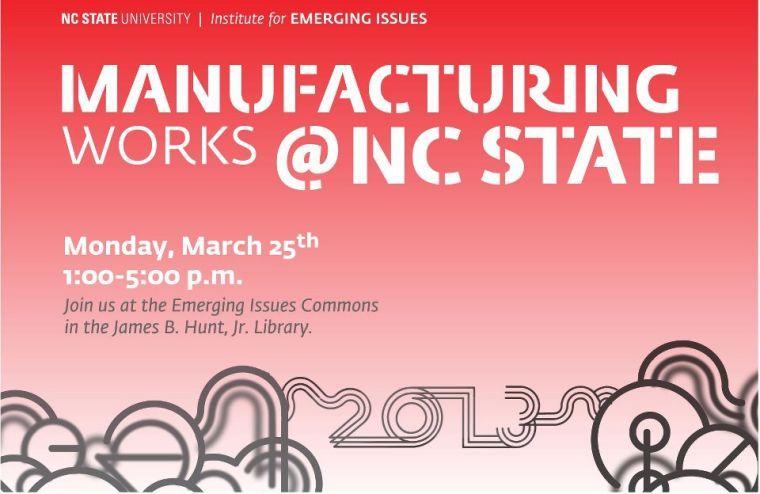

N.C. State alumni will share their thoughts on manufacturing and its relation to the state’s economy on March 25 from 1-5 p.m in the Hunt Library. The discussion is a part of ManufacturingWorks @NCState, a forum for students sponsored by the Institute for Emerging Issues and Technician. The forum seeks to create a dialogue between students, academics and industry leaders to learn about the rapidly growing and changing field.

Speakers will include Chris Clearman of GoPro, Rashida Hodge of IBM and Meghan McCann of Fujifilm Diosynth Biotechnologies.

Chris Clearman

Clearman graduated from the University with a bachelor’s degree in industrial design in 2010.

During Clearman’s undergraduate career, he worked for Hard Parts Design first as a fabricator and then as a designer, where he dealt with tractor attachments and accessories. Afterward, he interned at Techtonic Industries, which rehired him full-time after his graduation.

His education at N.C. State taught him about concept development, which he said involved “taking an idea and bringing it to life.”

His current job at GoPro, requires him to come up with ideas and figure out how to implement them. GoPro produces camcorders that can be mounted on users, allowing for more flexibility when taking photos or shooting video. The cameras were originally designed for sports enthusiasts, but now the company is trying to make them more mainstream, Clearman said.

Clearman researches how camera placement can create better shots for scuba divers underwater. He uses computer-aided design to simulate the design of metal parts, and then uses 3D printers to have a tangible copy of the parts. After he tests the concept, he redesigns it for manufacturing and later reassesses it for quality control.

Clearman only designs the mount and housing of GoPro cameras, while electrical engineers work on the camera itself.

As for the future of manufacturing, Clearman said he does not foresee a return to assembly lines and factories in the United States due to the outsourcing of cheap labor.

Instead, Clearman said he thinks the country will take a new approach to manufacturing with advanced engineering and design, but the nation will have to create more high-tech jobs to accomplish this goal.

“It’s hard to outsource design and creative thinking,” Clearman said. “We can push the envelope in ways other countries can’t, because America embraces creativity.”

Rashida Hodge

Hodge graduated from the NCSU with a bachelor’s degree in industrial engineering in 2002 and a master’s degree in industrial engineering in 2003.

She said the master’s program fit her very well, and her professors were very supportive of her academic and career pursuits. She was the recipient of many scholarships while attending N.C. vState, including a scholarship from the College of Engineering Endowment from Joseph Colson.

Quickly after her graduation, Hodge and a classmate started their own endowment fund, and later Hodge opened another fund called Real Hope for Next Gen.

“I wanted to do it when it was a sacrifice because that means I am giving up something for them,” Hodge said. “The important thing is to plant the seed and then continue to nurture it.”

At her current job at IBM, Hodge said she leads the strategic development and management of IBM’s supply chain strategy.

Hodge has worked at IBM for about 10 years and said she became a manager after two years, through which she said she developed “T-shaped skills — a breadth and depth of skills.”

“My career at IBM has been nothing short of fantastic,” Hodge said. “I am a fanatic about being an IBMer.”

Hodge worked in several global ventures with IBM, leading teams in Europe and Asia. Most recently, she said she had the opportunity to spend three and a half years in Slovakia leading one of IMB’s supply chain teams.

“I’m proud of the leader I have become,” Hodge said. “I’ve made decisions that ultimately made me the most competitive person that I could be and I have learned from each experience — good, hard, easy, successful and failures.”

Hodge said manufacturing is “continuously evolving,” and university curricula need to adapt to these changes.

“We need to build curriculums that teach students more than how to address a problem in a manufacturing plant,” Hodge said. “Industrial engineers need to be able to make a difference across the extended value chain. The world is changing, data is changing, and our skills need to evolve with it.”

Meghan McCann

McCann earned her bachelor’s degree from the University in 2012, majoring in chemical engineering and earning a minor in biomanufacturing. She hopes to obtain her master’s degree from N.C. State in 2016.

McCann said her education at the University prepared her to see problems that she might not be able to solve alone, and learned a great deal about biomanufacturing through N.C. State’s Biomanufacturing Training and Education Center.

“You actually had labs where you were working with bioreactors,” McCann said. “You got to touch it, see it and feel it before you actually got to do it.”

McCann also learned about the delicate ethics in her biomanufacturing education.

“When you are making things that go through the bloodstream you can’t afford to do it wrong and not admit it and fix it,” McCann said.

Now at her job at Fujifilm, she works with microbial and mammalian cells, which can be used to make vaccines, cancer treatments and antibodies, McCann said.

McCann said her GPA, internships, co-op and working 20 hours a week throughout school were major factors in allowing her to work at a place like Fujifilm, though she said she also had more opportunities than other recent grads because of her networking skills.

“I still have those mentors and still hang out with them when I get the chance,” McCann said.

Before working at Fujifilm, McCann did a co-op at Biogen-Idec, and interned at Novartis Vaccines and Diagnostics, and Baxter Healthcare.

She is a member of the American Institute for Chemical Engineers and the International Society for Pharmaceutical Engineers.

ManufacturingWorks@NCState will take place:

- When: Monday, March 25, 1-5 p.m.

- Where: Hunt Library Institute for Emerging Issues Multi-Purpose Room (Second Floor)

Who will be there?

- Business experts and leaders

- Alumni in the manufacturing field from companies like IBM, Fujifilm Biotechnologies, GoPro and the North Carolina Technology Association

Why is it important?

- North Carolina’s leading economic machine is the manufacturing industry.

- Students will have the opportunity to interact with panelists and network with industry representatives.

Get Registered:

- http://manufacturingworksncstate.eventbrite.com/