Notable alumni spoke about the past, present and future of the manufacturing industry with faculty and students Monday at the Institute for Emerging Issues’ forum, ManufacturingWorks@NCState.

The Institute for Emerging Issues partnered with Technician to present the forum, which focused on engaging students in a resurgence manufacturing landscape.

Marshall Brain, founder of HowStuffWorks; Warren Ginn, founder of GinnDesign and Brooks Raiford, CEO and president of the N.C. Technology Association, were among the speakers at the event.

Brain was the keynote speaker of the event, sharing his expertise in entrepreneurship and visits to more than 40 American factories while working with National Geographic. He said modern factories are fully automated and are employing technology to their advantage. He visited a flour-mill factory whose camera system photographed each grain of wheat to validate it, and if it didn’t meet criteria, it would be ousted.

“The amount of precision and scrutiny you can get in quality control is just outstanding,” Brain said. “One could make a good argument that [having automated manufacturing work floors] is a good way of getting humans out of harm’s way.”

In the past, humans were solely involved in the manufacturing process, said Brain. But now, with fully automated plants, companies from North Carolina are able to insource jobs in the United States.

Manufacturing is changing radically and North Carolina is changing around it, said Gart Davis, co-founder and partner of Spoonflower, a textiles printing firm in Durham. Davis echoed Brain’s comments about globalized companies in the state that have brought their production plants back to the United States due to advances in automation.

“Companies can now inshore jobs, instead of sending them off,” Davis said. “It has allowed many startup companies to take advantage of new opportunities.”

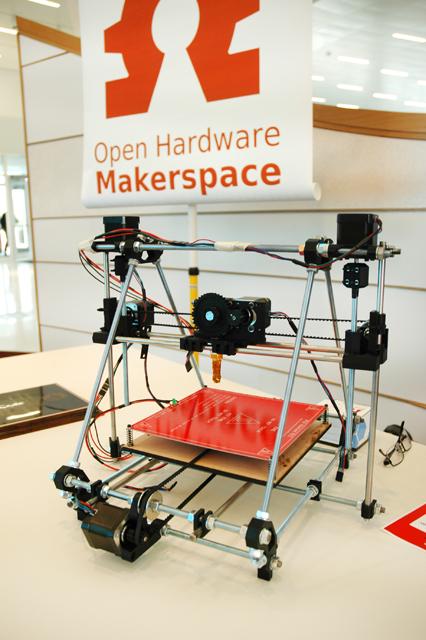

The invention of 3-D printing allows for ideas to come to life almost instantly. Three-dimensional printing makes manufacturing accessible all the way down to the elementary school level, said Brain.

These printers can print in plastic, metal and other materials, said Chris Clearman, senior designer for GoPro cameras. All you need is an idea and access to a printer to make your idea a reality, said Brain.

“I use 3-D printing every day at my job,” Clearman, a 2010 graduate in industrial design, said. “I’m excited to see where this goes.”

Websites like Kickstarter and IndieGoGo are redefining the timeline for funding manufacturing projects and ideas. Ten years ago, nothing like this could happen, said Brain.

“Now, if you can imagine it, you can create it,” Brain said.

Organic Transit in Durham created a covered bicycle that allows the driver to carry a bit of cargo and choose between manual pedaling and an electric motor, according to Brain. Organic Transit manufactures most of the parts for its bicycle invention by hand, allowing for slower output of its product.

“This is a credible way of showing that anybody can manufacture their ideas,” said Brain.

Raiford said the state’s current unemployment rate is two percentage points higher than it would otherwise be if manufacturing in N.C. was the same as the average among all states.

Meghan McCann, an associate scientist at Fujifilm Diosynth Biotechnologies, said even pharmaceutical companies are trying to go green while still developing their products in the safest way possible.

“Pharmaceutical companies aren’t traditionally environmentally friendly,” McCann said. “We’re trying to change that.” McCann’s company is looking to use single use bioreactors instead of large vessels to minimize energy used during cleaning and sanitation processes.

GoPro is trying to use more paper-based products and is taking steps toward sustainability, said Clearman.

After the panel discussions, students and faculty stayed behind to continue discussing how to engage students in manufacturing and make rebranding into a sexier, more appealing field. At the end of the day, those in attendance discussed how to redefine manufacturing, and leaders from the Institute for Emerging Issues will use their feedback to keep the dialog — which was exemplified today — flowing.