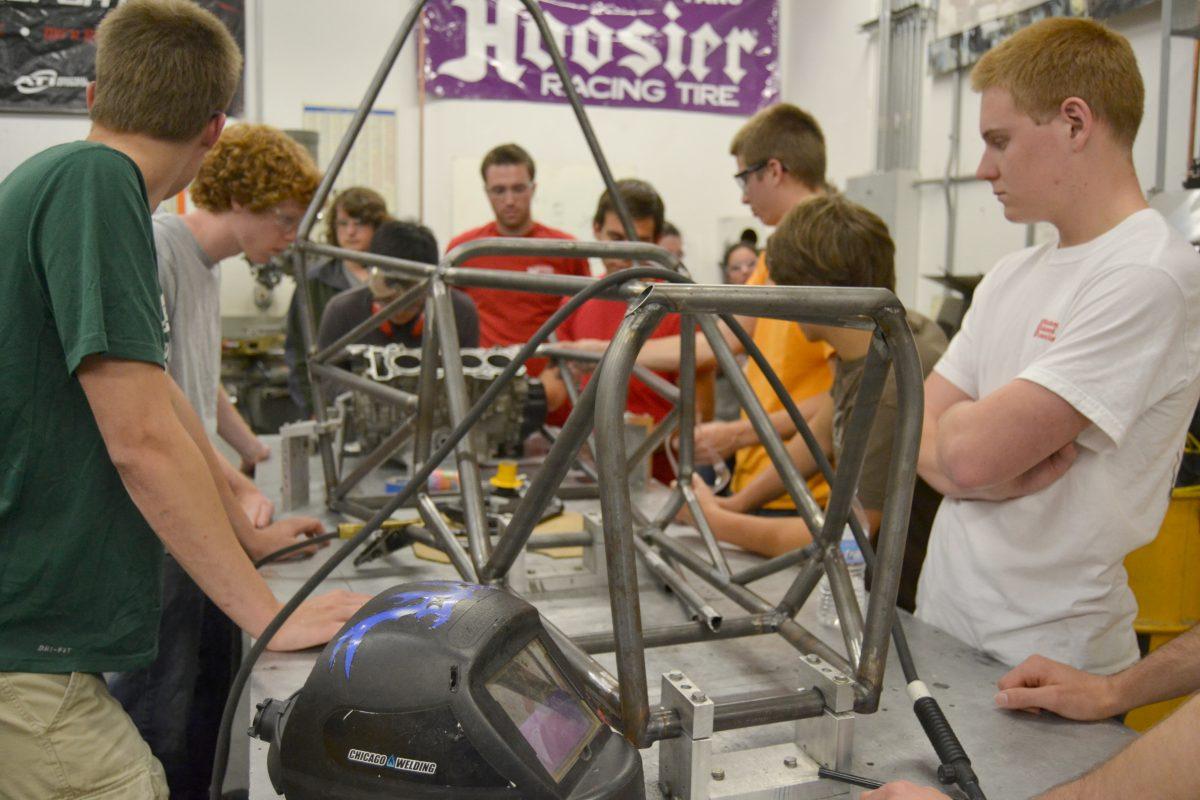

Unlike most clubs, Wolfpack Motorsports is a team divided: Team Baja and Team Formula make up this club of gearheads who design, build and ultimately race cars. Each team designs and constructs cars that are entered into several competitions sponsored by the Society of Automotive Engineers.

Wolfpack Motorsports members study varying fields but most study engineering and have a keen interest in automotive design. At their core, SAE competitions evaluate automotive engineering.

“A lot of people forget it’s not just some boys who want to go racing. There’s a large engineering aspect to [racing],” said David Bohle Jr., co-captain of Team Baja and junior in mechanical engineering.

Students learn something a classroom cannot teach by working with car parts and systems in Wolfpack Motorsports.

“One of the really cool things is that a lot of the things we do here you aren’t learning in class, like gear calculations,” Bohle said. “That may be senior or graduate level stuff but Nathan and I were juniors teaching ourselves how to do it.”

Both teams of the Wolfpack Motorsports club are required to create a fast, well-running car. Tyler James, a senior in agriculture and environmental technology and a member of Formula, said he believes usability is a key part of the car’s design.

“The car is a small scale open wheel auto cross car. The basis of the design is for a general everyday average Joe to go out and take this car to an autocross course and have a good time,” James said.

The bulk of the hours put into each car come from the design and building processes. Team captains spend anywhere from 30 to 40 hours a week on their cars, while new members are expected to put in five to 10 hours a week.

The design process itself involves several steps for a single part. Nathan Brace, a senior in biological engineering and team captain of Team Baja, is trying to use old connections and last year’s performance to improve the car.

“Every year after competition we restart the design process and focus on a component we really want to improve on for the next year,” Brace said. “We sent out our designs to our alumni base to get some feedback and then use their suggestions to keep refining our ideas.”

Each competition spans several days. For both teams the first day consists of talking about the car in design reviews, mock business pitches and cost reviews along with testing the weight and other engineering checks. After that teams move on to other dynamic tests such as a brake lock test, acceleration run or even a tilt test where the car runs at a 60 degree tilt making sure no liquids leak out.

The last day, consisting of endurance tests, is something several members look forward to. Formula uses two drivers for 20 minutes each in their endurance test.

However in that competition Josh Goughnour, a junior in mechanical engineering and a member of Formula, said many teams don’t pass the dynamic events of the previous days.

“During the dynamic events you have a small window to pass them and many teams don’t,” Goughnour said. “We did pretty well in a lot of the dynamic events; we were top 20 in all the events.”

In Baja’s competition, 100 people drive their cars on the track at once for a four-hour race. The amount of cars on the track and the stress to cars mean many vehicles are forced off the track for short periods of time.

“At competition the whole goal of the course designers is to push your car beyond its limits and they succeed probably nine times out of 10,” Brace said.

With such strenuous conditions and 100 cars on the track, many cars don’t make it far before breaking or needing repairs. Baja did well in its competition in Rochester against the odds.

“Probably 50 percent of the cars are out on the first lap. In Rochester, we got fourth place in endurance,” Bohle said. “Our car didn’t break and we only stopped three times for fuel.”

For Taylor Gettys, a senior in mechanical engineering and team captain of Formula, when his car runs and does well it validates the time put into the car.

“It’s really stressful when you’re making the car but once you see the car come together and see it actually work and go fast that’s when you feel the best about this,” Gettys said.

Many student in Wolfpack Motorsports end up going on to jobs in the automotive industry not necessarily related to racing.

“We have a lot of alumni in NASCAR or organized racing. Beyond that, we also have a lot of people go to aftermarket parts designers and parts suppliers for different motorsports crews,” Gettys said.

Along with opportunities to work with motorsports crews or NASCAR, Bohle and Brace said that team members also end up going into related but not necessarily automotive fields. Many members go on to get masters in mechanical engineering or work for companies such as Cummins and Caterpillar.

For anyone interested in automotive engineering or cars in general, the Wolfpack Motorsports club provides a great opportunity to learn things that classes may not teach and to create a car that can withstand even the toughest tests in a competition.