Airbrushing leads to large-scale manufacturing of carbon fibers

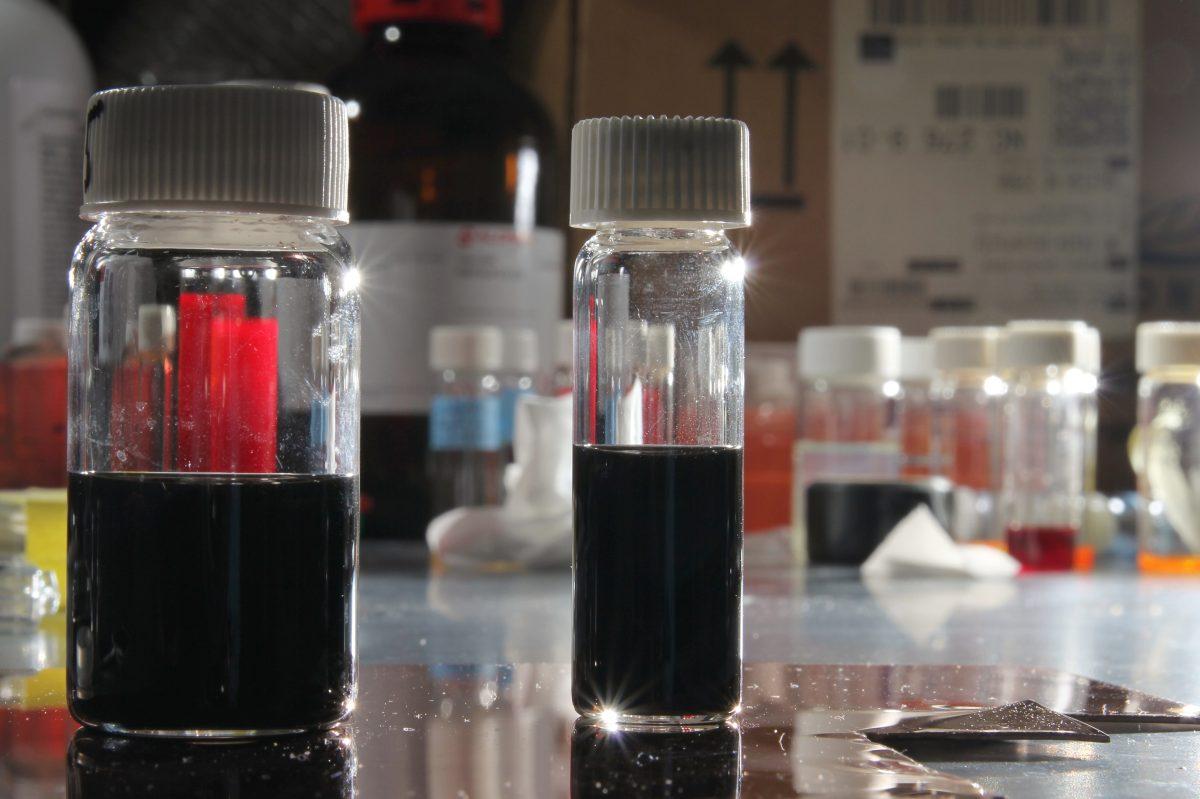

N.C. State researchers recently published a study about the production of carbon nanofibers by employing a technique called airbrushing.

Generally, airbrushes are used to cover various surfaces with paint. However, according to Professor Joseph Tracy, who oversaw the research, airbrushing is a simple way to deposit large areas of catalyst particles.

“Applications where you wanted a large area deposition that’s economical, this [airbrushing] would be a viable way to do it,” Tracy said. “It makes the application more technologically feasible.”

The process of creating nanofibers involves growing the nanoparticles, then airbrushing them to deposit them, and then having a coating of nanoparticles on the surface and then the nanofibers are grown from the nanoparticles, according to Tracy.

Bryan Anderson, who co-authored the paper, said that there would be an effect on the entire biomedical industry.

“We can use these carbon nanofibers to punch through cells, and you can use them for such things as drug delivery,” Anderson said.

Anderson also said you can take a gene or a protein and attach them to the end of the carbon nanofibers, punch them into a cell and effectively insert those molecules into cells.

The electronics industry

can use carbon nanofibers as an electrode to conduct current from one electrode to another, according to Anderson.

A carbon nanofiber is made out of a sheet of carbon called graphine and it is rolled into a cone and if you stack these cones on top of each other that would give you the carbon nanofiber, according to Tracy.

These nanofibers serve a wide variety of purposes across a multitude of industries. They are widely used throughout the world today.

This research demonstrates a relatively new application of nanomaterials. In an industrial setting there is interest in scaling them and making large amounts of them, or to cover large surfaces, according to Tracy.

Airbrushing the nanoparticles serves as useful tool in roll-to-roll processing, which is a method where you have some substrate on one roll and you unroll it and conduct a process on it, and then rolling it onto another roll, and this is an accepted standard for large scale manufacturing.”

Ultimately, by using the process of airbrushing the researchers have effectively laid a foundation for large-scale manufacturing of carbon nanofibers.

The research paper was titled Airbrushed Nickel Nanoparticles for Large-Area Growth of Vertically Aligned Carbon Nanofibers on Metal (Al, Cu, Ti) Surfaces, and it was published in ACS Applied Materials & Interface.