Dr. Emily Christiansen, a post doctorate resident in the department of clinical sciences, prompted the creation of a splint for an injured turtle’s leg with a 3-D printer. It was developed by putting the turtle’s broken leg through a CT scan and was then finished by the biomedical engineering department of NCSU. " />

Dr. Emily Christiansen, a post doctorate resident in the department of clinical sciences, prompted the creation of a splint for an injured turtle’s leg with a 3-D printer. It was developed by putting the turtle’s broken leg through a CT scan and was then finished by the biomedical engineering department of NCSU. " />

SOURCE: ncsu.edu

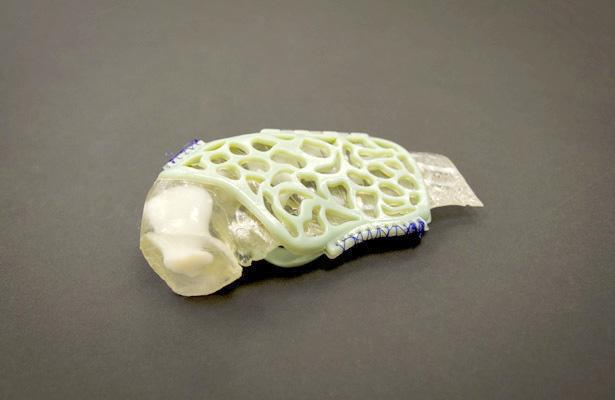

Dr. Emily Christiansen, a post doctorate resident in the department of clinical sciences, prompted the creation of a splint for an injured turtle’s leg with a 3-D printer. It was developed by putting the turtle’s broken leg through a CT scan and was then finished by the biomedical engineering department of NCSU.

On the Atlantic Coast, thousands of turtles become stranded due to injuries from harsh waves, boats and other hazards of the sea each year. Most of these injured turtles are taken to the North Carolina Wildlife Resource Information Commission where they are rehabilitated and released back into the wild.

Dr. Emily Christiansen, a post doctorate resident in the department of clinical sciences who works closely with the N.C. WRC, recently came across one particular case in which a turtle had fractured its front, right leg. According to Christiansen, this injury made it impossible for the sea turtle to swim at the capacity it needs to survive in the water.

According to Christiansen, the turtle came from Beaufort, N.C. A few recreational boaters discovered the creature afloat at the surface of the water. The boaters turned the turtle over to Coast Guard boats that sent the turtle to the NC WRC, and it eventually found its way into the care of Christiansen.

Christiansen knew the current techniques for healing a fractured turtle fin but, according to her, traditional splints and casts can break down and deform due to salt water exposure. They can also cause scratching and other external wounds to the turtle due to the extensive movement turtles undergo when swimming through the sea.

Christiansen said she hoped for a better method and one that could eliminate these flaws and create the optimal cast for this specific turtle’s condition.

By chance, she came across a news article a few weeks before encountering the injured turtle. The article discussed a New Zealand engineering student who created a 3-D printed cast for his injured wrist. 3-D printing is a relatively new technology that brings a digitally designed form into a tangible product by adding layers of material. Potentially, any shape can be made through a 3-D printer– even the fin of an injured sea turtle.

“Initially I blew the idea off as impractical because where are we going to get that technology from?” Christiansen said, “In thinking about it more, I figured we have an engineering department. I bet we could get someone to do that.”

She was right.

According to Christiansen, after putting the turtle’s broken leg through a CT scan to obtain an accurate 3-D rendering, the scan was passed onto the biomedical engineering department at N.C. State. A long and arduous process commenced to construct the cast, but eventually it resulted in a fully functioning splint for the sea turtle.

During the weeks the splint was being created though, the injured animal’s leg had improved. Its wound had been slowly closing and repairing itself during the turtle’s waiting period for its high-tech splint.

“The funny thing about turtles is they will heal in spite of us,” Christiansen said. “He was kind of half healed by the time we put the splint on, but at that point we just wanted to see if it would work.”

So she and some of her colleagues, including Craig Harms, an associate professor of aquatic wildlife and zoologic medicine at N.C. State, continued to pursue the splint. They attached it to the still healing turtle, and the results were positive.

“It was really pretty amazing,” Harms said. “The first time we put it on, he flipped his flipper a couple times like he didn’t like it, but then he just started swimming around and the flipper propelled him really well.”

Christiansen agreed with Harms as she observed just how impressive the results were.

“It fits flush on his flipper, so there’s not a whole lot of extra tension in the water,” Christiansen said. “It fit great. It stayed on. The plastic material did not break down in salt water. All in all it was very successful.”

Because of this success, Christiansen said she feels the 3-D printing technique could be the way of the future for splinting. It could aid many turtles, humans and other animals in the healing process of severe fractures and other damages.

But according to Christiansen, there are still a few obstacles to overcome before 3-D printed splints become a common, everyday product.

“I think there will be more challenges as we try to scale it up,” Christiansen said. “We are looking for other cases to try it on. It is very successful as a concept, so I think it has some great potential.”