NC State’s College of Textiles accepted a $639,112 grant from the Walmart Manufacturing Innovation Fund on Sept. 30th.

The Walmart Corporation and the United States Conference of Mayors gave these grants to six colleges in an effort to bring manufacturing jobs back to the United States.

Joe Quinn, the senior director of Public Affairs and Government Relations for Walmart, addressed attendees during a conference hosted in the Convocation Center at the College of Textiles building on Centennial Campus. The conference was attended by NC State faculty and business leaders from around the triangle and abroad.

The grant was awarded to the College of Textiles so research could be done to develop a manufacturing system that integrates digital printing with cut and sew assembly.

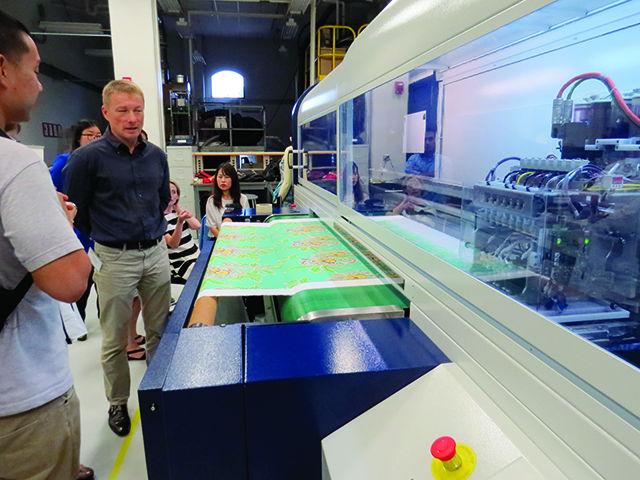

A ribbon cutting ceremony was held to unveil the first model of the printing system, designed by MS Printing Solutions, to be constructed in the United States. A demonstration of the system’s capabilities showed that the new machines are capable of printing complex designs onto natural and synthetic fabric at a rate of 100 meters per hour using four colors and 50 meters per hour using eight colors; a fraction of the time it used to take to produce comparable goods in the past.

The goal of this project, according to a press release, is to bring manufacturing jobs back from overseas. It will allow suppliers to respond to demand quickly without having to overstock, which will save money.

The field of digital textile printing is of ever increasing interest for manufacturers as an alternative to traditional textile production methods. Digital textile processes could decrease the reliance that manufacturing companies currently have on overseas production.

The new digital textile printer printing a design in the new lab as visitors look on at the College of Textiles on Wednesday. A ribbon cutting ceremony was held to unveil the new machine, the first model used in the United States. A demonstration of the system’s capabilities showed that the new machines are capable of printing complex designs onto natural and synthetic fabric at a rate of 100 meters per hour using four colors and 50 meters per hour using eight colors; a fraction of the time it used to take to produce comparable goods in the past.