Many associate fossil fuels and industrial waste as the main culprits of pollution , but Associate Professor Sanjay Shah has recognized farm waste to be a large contributor. He’s now developing a way to reduce harmful emissions and conserve energy within the farming industry.

Shah, a researcher in biological and agricultural engineering, recognized a major problem within the chicken and swine farming business. He found these animals being raised were contributing to the degradation of the atmosphere through the addition of harmful emissions, such as ammonia.

“When raised inside a storage house, the animals naturally defecate, and having a large number of them gives way for their feces to accumulate,” Shah said. “Over time the accumulated feces will breakdown and release toxic gases , like ammonia, which then are expelled into the outside air.”

Shah, along with a research team from West Virginia University, worked to develop a technology that could potentially resolve this issue.

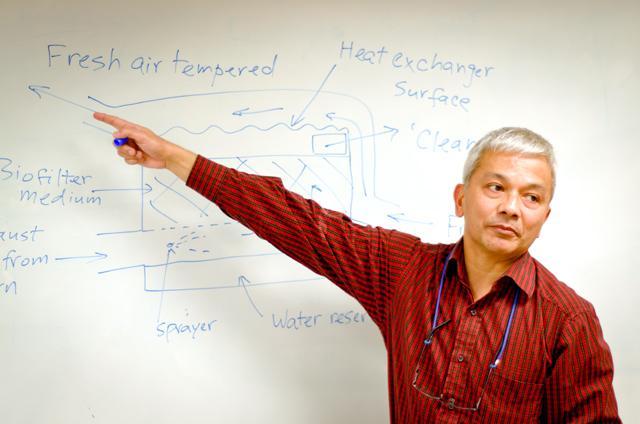

His team eventually devised a plan to create a biofiltration system that would take in the heated polluted air from the storage houses and essentially clean it using an organic medium, composed of compost material, before it was released back into the atmosphere. This seemed to be a good idea, but it posed an issue when it came to replacing the exported heated air from the house, as it would increase energy production costs to replenish it. Shah and his team found a solution that would satisfy both problems: producing a biofilter coupled with a heat exchanger that took in clean outside air, warmed it, and released it back into the houses.

“Our thinking was that if we could recover some of the heat from the polluted air being transported into the filter and use it to warm the neutral outside air being taken in, then we could reduce the cost to reproduce it,” Shah said in justification for the addition of the exchanger.

Shah and his team created this project in 2004, and since then were successfully able to prove the coupled biofilter-heat exchanger concept; the filter reduces harmful air pollutants from being released into the air while also lowering energy consumption within chicken and swine barns.

“With the system, we were able to remove high concentrations of the pollutants from the air by about 80 percent or greater, and use the heat from that flow to warm the replacement air,” Shah said.

According to a natural resources extension specialist on the team, Tom Basden , the team was “very involved with all aspects of the study, including the design, up keep, instrumenting , data collecting, proper function of the poultry house, air exchange and temperature and humidity control.”

After being able to verify that the biofilter-heat exchanger concept worked, the next step for Shah and his team is to be able to identify the bugs, refine the system, and put it to use.

“What we would like to see happen next is to have an approved system installed in a commercial storage house,” Shah said. He also went on to explain that him and his team, “feel that this system should be tested in a different environment, particularly one that has a colder climate, also with smaller livestock where a larger input of energy is needed to ensure proper development.”

This type of situation would truly put the filter to the test, according to Shah, proving it’s versatility and capabilities.

William Winner, a professor of environmental science and natural resources, said Shah’s project fits into a larger picture of environmental science innovation.

” N.C . State is a hot bed for research on innovative approaches for energy issues, spanning topics ranging from nuclear biology to energy in the nucleus of atoms to production of liquid fuels from sunlight,” Winner said. “[We’re] at the forefront of bringing these technologies to North Carolina and beyond.”