The University is striving to prove it is the autobahn of innovation by turning science fiction into science fact– developing novel industrial applications using ionized gases or plasma.

At the department of nuclear engineering, professors Steven Shannon, Mohamed Bourhom and John Gilligan are doing research on what they hope to be a more effective process of developing new energy-saving technology.

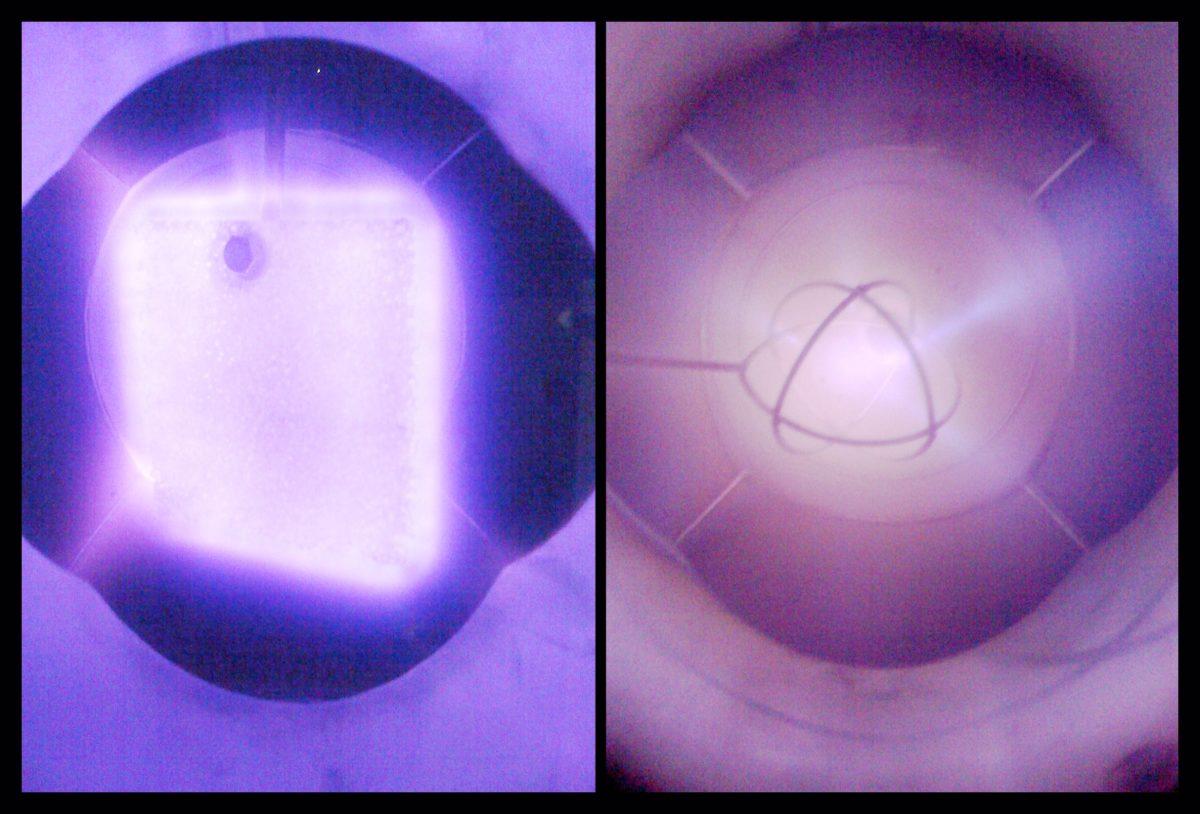

For instance, Shannon and his colleagues are trying to develop a process where they take a porous piece of aluminum and ionize silica compounds onto the pores through the use of a fusor in a IEC (Inertial Electrostatic Confinement). A fusor is a vacuum chamber designed to create nuclear fusion. Hopefully, the process will allow for the creation of more effective solar panels.

The ionization process will also help in the creation of smaller and more effective microchips. Shannon explained that the differences between the microchips’ processing power was the spacing of its integrated circuits. The smaller the spacing, the faster its’ processing power.

“Without plasma, you are capped off to a max of a couple micro-meters,” he said, thus plasma ionization will hopefully allow the circuits to be spaced out in the nanometer range.

“That’s the difference between, say, 10 megahertz and 3 gigahertz,” Shannon said.

Bourham and John Gilligan of the nuclear engineering department are also doing research in plasma applications for defense applications. Their research entails the development of high-density plasmas that will be used in hyper-velocity launches.

“Plasma ionization will be used to propel payloads in excess of several kilometers,” Bourham said.

Plasma ionization will be used in the development of rail guns and electro-thermal guns. Rail guns are devices that use and pass an electric field that interacts with a magnetic field produced by a rail system. This accelerates the projectile. Electro-thermal guns run on a similar principle but they would be used to start off the projectile from rest.

Bourham has also collaborated with Marion McCord, an associate professor in textile engineering chemistry and science, to develop surface modifications on fabrics by using atmospheric plasmids.

“This extends to grafting fabrics with antimicrobial agents,” he said.

This will, in essence, provide the fabrics with permanent antimicrobial features. Medical and military apparel will be then created from these modified fabrics.

In the department of mechanical and aerospace engineering, associate professor Alexei Saveliev is researching the development of a new ignition system

“The new ignition system would use a fuel-jet spray that would be ignited through the application of a plasmatic discharge,” he said.

Hopefully, the process will not only make engines more efficient, but also more environmentally friendly.

“This technology will reduce the pollutants of the internal combustion engine by replacing the glow-plugs,” Saveliev said.

The researchers in these new fields of science hope their research will create a bridge from an abstract novelty to a field of science that will also contribute to our society and economy.