Make a device that seriously improves resource sustainability on campus that is easy to use, makes a significant difference and is cheap. You only have 45 hours to do so. This was the task given to 11 teams and 45 students at NC State’s first-ever Make-a-thon, a competition where students were tasked with designing and testing a product under seemingly impossible time constraints with the goal of improving either water, waste or energy sustainability on campus. One team not only won, but also built a working prototype of its device, KnowURShower.

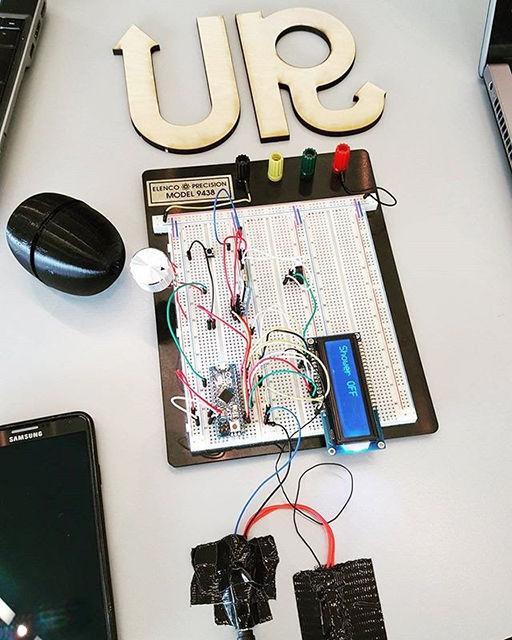

Four students, Brian Iezzi, Michael Meli, Bryan Murphy and Derek Whatley, all entered the Make-a-thon under the water category and worked together to create KnowURShower, an easy-to-use shower add-on that measures the water output of a shower, allows the users to set a water budget goal for themselves and adjust the shower flow to meet their goals. The device conveys the information collected using LED lights as opposed to gages and numbered readings.

“As you adjust your flow, the device changes colors,” said Iezzi, a senior studying textile and material science engineering. “If the lights are red, you’re using water very quickly, and if the lights are green, you’re using water slowly.”

Iezzi said the device can be installed easily between the showerhead and the water source pipe and allows for flow control without the need of a special showerhead.

“It’s really just a matter of unscrewing your showerhead, screwing the device on and screwing your showerhead back on,” said Murphy, a senior studying electrical engineering. “We wanted to make it as accessible to everybody as we could, making it simple and easy to install with any showerheads out there.”

Meli, a senior studying computer and electrical engineering, said one way to power the device is to use the water flow from the shower. The flow of the water turns a small turbine in the device that would generate the energy needed to power the KnowURShower, eliminating the need for electricity and avoiding the device wasting power when not in use

“Water and electronics don’t really mix well, so we had to make the device airtight,” Murphy said. “A user doesn’t necessarily know how much water they are using, so we tried to quantify that using color coding.”

Meli said Make-a-thon was more multidisciplinary than a Hack-a-thon because it involved more than just software and electronics and the actual creation of a physical product.

“Sustainability is something I have been exploring the past year or so, but I think the cool thing about Make-a-thon was that it gave me a reason to start tinkering around with electronics,” Murphy said. “I got to start to work together with a team to put to use the different concepts and ideas I’m learning in class.”

The team had to work together and allocate work similar to in the workforce, splitting up the work effectively to make the contest’s deadline. Murphy and Iezzi were in charge of 3-D design, creating the product’s physical structure, while Meli and Whatley created an electrical demo of the product for demonstration purposes. They even created an app for the product that recorded all of the water usage data collected from the device via Bluetooth.

The teams at Make-a-thon were given access to water usage data from residence halls and other buildings around campus, showcasing areas where improvements could be made. The KnowURShower team did a case study on Wolf Ridge Apartments, due to the team’s ability to record daily water usage data across the apartments. The team figured out how many showers were in the location and how much water was being used.

Iezzi said the KnowURShower team used this data to calculate how much water the devices were capable of saving and the return on investment of the KnowURShower based on the costs saved in water and the price of the device itself, calculated based on the cost of the materials needed to build the product. The team compared its product’s cost to the cost and price of other real products on the market and found its product to be cheaper to make and to sell.

“We wanted to prove that installing the device in all the dorms at Wolf Ridge would be cost effective, which isn’t easy considering water is realistically cheap,” Murphy said. “If you want to have a return on investment, you have to have a cheap product.”

Murphy said the data made it clear to the team that the residence halls around campus were where the most water is used and that a large portion of water usage comes from the showers, making them the obvious target area to improve.

“The other teams did not really have a prototype, they just had the idea, but we actually engineered our idea into a solution,” Meli said. “You can come up with any idea easily, but if it’s not feasible, then there’s no value to it.”

The team members said they could realistically see their product being made for commercial use and that they hope to continue working on it.